- 322-328 N 9th St.

Terre Haute, IN 47807 - 812-234-1569

- www.ind-supply.com

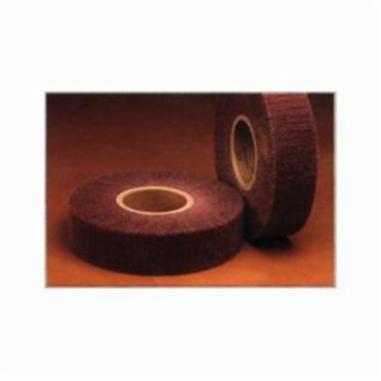

Scotch-Brite 051141-55749 Hard Density High Strength Match and Finish Unmounted Non-Woven Flap Brush, 4-1/2 in Dia, 4 in W Face, Coarse Grade, Aluminum Oxide Abrasive

- Item Code: 3M 051141-55749

- Brand: Scotch-Brite

- Mfg Part No: 051141-55749

- Manufacturer: 3M

- Unit Size: 1

Description

Scotch-Brite™ match and finish high strength flap brush is durable and aggressive, great for blending and finishing on a variety of metals. Scotch-Brite™ match and finish high strength flap brushes combine aluminum oxide mineral and our non-woven nylon fibers with resin. Sharp-cutting aluminum oxide mineral leaves a fine finish, while the spongy, open web responds to surface irregularities and maintains part geometry. This brush is one of the most durable among all the Scotch-Brite™ flap brushes, so it's good for graining stainless steel, blending handling marks and imperfections, cleaning around welds and light deburring. Easy attachment Scotch-Brite™ match and finish high strength flap brush may be used on the 3M™ 1HP match and finish sander (sold separately) and is available in 5/8-11 threaded inserts for easy thread on/off attachment as well as a 4-way keyway attachment system. Under normal use (abiding by recommended rpm), the Scotch-Brite™ match and finish high strength flap brush minimizes chatter risk. As the brush spins, flaps rotate centrifugally and make continuous contact with the workpiece. By lapping the surface, the flaps reduce the residual traces or marks that tend to be left by singular discs or discs ganged on a shaft. Welding, bending, stamping and other fabrication processes can seriously mar the mill finish of stainless steel and other metals - requiring a lot of time and many tricky, painstaking steps to restore the finish to its original condition. Scotch-Brite™ flap brushes are often the last step in a Series -ushered in to a sequence when the surface is ready for a final finish. For weld blending and finish restoration, flap brushes may be preceded by other abrasives like a fiber disc for weld removal and a belt that sets the grain. With a little practice, users can feather in and out of the repair area with their flap brush, reducing chatter and marks. Some flap brushes are more durable, whereas others are more aggressive. Non-woven technology makes our Scotch-Brite™ industrial abrasives unique. A combination of fiber strands, resin and abrasive mineral forms a thick, open web. The spring-like nature of the fibers responds to contours and effectively removes unwanted burrs, soils and contaminants while maintaining the geometry of the workpiece which in turn reduces rework and boosts productivity. Gaps in the web allow swarf to escape, so debris does not clog the mineral. Fibers in t

Features

Back To Top- Flap construction reduces risk for chatter

- Easy thread on/off attachment

- Aluminum oxide cuts sharp and leaves a soft scratch pattern

- Open web is load-resistant, prolonging abrasive service life

- Open web is spongy and responds to surface irregularities of the part

Tech Specs

Back To Top| Abrasive Material | Aluminum Oxide |

|---|---|

| Attachment Type | Threaded |

| Center Hole Thread Size | 5/8-11 |

| Face Width | 4 |

| Grade | Coarse |

| Interleaf | No |

| Maximum Speed | 3500 |

| Type | Hard Density High Strength Match and Finish Unmounted |

| UPC | 05114155749 |

| Wheel Diameter | 4-1/2 |

Applications

Back To TopRelated Items

Scotch-Brite™ 048011-01161 Medium Density Unmounted Non-Woven Flap Brush, 6 in Dia, 1 in W Face, Fine Grade, Aluminum Oxide Abrasive

LEARN MOREScotch-Brite™ 048011-01162 Medium Density Unmounted Non-Woven Flap Brush, 6 in Dia, 1 in W Face, Very Fine Grade, Aluminum Oxide Abrasive

LEARN MOREScotch-Brite™ 048011-01163 Medium Density Unmounted Non-Woven Flap Brush, 6 in Dia, 2 in W Face, Medium Grade, Aluminum Oxide Abrasive

LEARN MOREScotch-Brite™ 048011-01164 Medium Density Unmounted Non-Woven Flap Brush, 6 in Dia, 2 in W Face, Fine Grade, Aluminum Oxide Abrasive

LEARN MOREScotch-Brite™ 048011-01167 Medium Density Unmounted Non-Woven Flap Brush, 8 in Dia, 1 in W Face, Medium Grade, Aluminum Oxide Abrasive

LEARN MOREScotch-Brite™ 048011-01171 Soft Density Unmounted Non-Woven Flap Brush, 8 in Dia, 2 in W Face, Fine Grade, Aluminum Oxide Abrasive

LEARN MOREScotch-Brite™ 048011-01175 Medium Density Unmounted Non-Woven Flap Brush, 8 in Dia, 2 in W Face, Super Fine Grade, Silicon Carbide Abrasive

LEARN MOREScotch-Brite™ 048011-01177 Medium Density Unmounted Non-Woven Flap Brush, 8 in Dia, 2 in W Face, Very Fine Grade, Aluminum Oxide Abrasive

LEARN MOREScotch-Brite™ 048011-01178 Medium Density Unmounted Non-Woven Flap Brush, 8 in Dia, 2 in W Face, Medium Grade, Aluminum Oxide Abrasive

LEARN MOREScotch-Brite™ 048011-01179 Medium Density Unmounted Non-Woven Flap Brush, 8 in Dia, 2 in W Face, Fine Grade, Aluminum Oxide Abrasive

LEARN MOREScotch-Brite™ 048011-01182 Medium Density Unmounted Non-Woven Flap Brush, 8 in Dia, 3 in W Face, Fine Grade, Aluminum Oxide Abrasive

LEARN MOREScotch-Brite™ 048011-01184 Medium Density Unmounted Non-Woven Flap Brush, 8 in Dia, 4 in W Face, Very Fine Grade, Aluminum Oxide Abrasive

LEARN MOREScotch-Brite™ 048011-01185 Medium Density Unmounted Non-Woven Flap Brush, 8 in Dia, 4 in W Face, Medium Grade, Aluminum Oxide Abrasive

LEARN MOREScotch-Brite™ 048011-01186 Medium Density Unmounted Non-Woven Flap Brush, 8 in Dia, 4 in W Face, Fine Grade, Aluminum Oxide Abrasive

LEARN MOREScotch-Brite™ 048011-01188 Medium Density Unmounted Non-Woven Flap Brush, 12 in Dia, 2 in W Face, Medium Grade, Aluminum Oxide Abrasive

LEARN MOREScotch-Brite™ 048011-01189 Medium Density Unmounted Non-Woven Flap Brush, 12 in Dia, 2 in W Face, Fine Grade, Aluminum Oxide Abrasive

LEARN MOREScotch-Brite™ 048011-01190 Medium Density Unmounted Non-Woven Flap Brush, 12 in Dia, 2 in W Face, Very Fine Grade, Aluminum Oxide Abrasive

LEARN MOREScotch-Brite™ 048011-01195 Medium Density Unmounted Non-Woven Flap Brush, 6 in Dia, 2 in W Face, Very Fine Grade, Aluminum Oxide Abrasive

LEARN MORE